Maintaining a consistent ventilation level with quality cigarette production is a top priority for every producer.

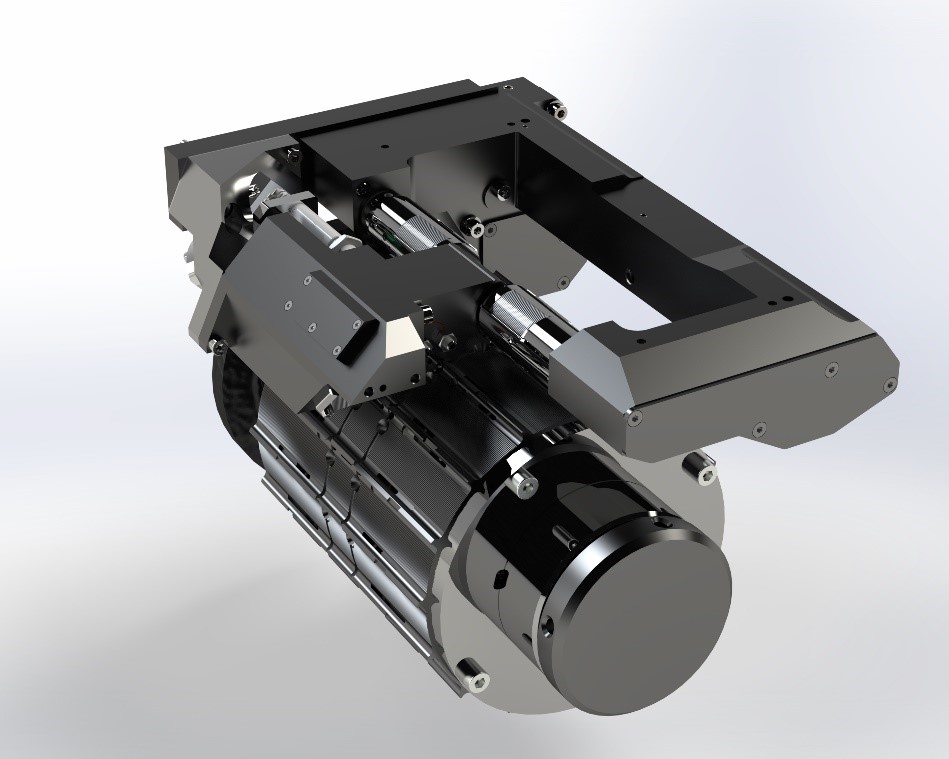

In addition to our complete online laser perforation system, TMQS offers components for the existing single-rod Protos laser front-end. This includes beam splitters, laser drums, cams, and all necessary minor components, supporting a wide range of perforation distances (11-20 mm, with an optional extension up to 26 mm) and various cigarette diameters.

TMQS also provides a conversion service from the 2 o’clock to the 12 o’clock system, facilitating the unification of your production fleet under a single standard if desired.

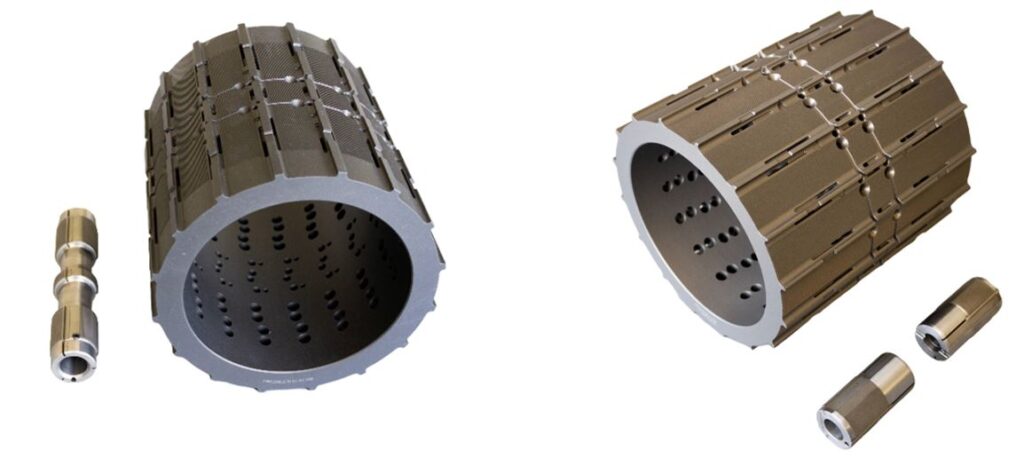

TMQS offers both FN or FA of standard and improved versions of the laser rolling drum. The improved version features a cutting-edge “black” coating that protects the drum’s surface from damage caused by the laser beam—even in instances of missing cigarettes—by ensuring better beam power distribution across the drum.

The unique internal geometry of the drum’s holes and vacuum channels optimizes vacuum distribution, allowing for a smooth transition from the start to the end of the perforation process.

Additionally, the enhanced laser cams (rollers) FA solid or FN split versions include an extended gripping area, which increases the rolling track of perforated cigarettes and prevents slipping. This design not only reduces wear on the roller surface but also extends the rollers’ lifespan, particularly when combined with the specially developed coating.

Benefits

- Advanced Technology: Utilizing durable, high-quality materials and innovative coatings for enhanced performance and longevity.

- Full Compatibility: TMQS solutions seamlessly integrate with OEM single-rod Protos, ensuring smooth operation without hassle.

- Variety of formats: Supporting a wide range of standard diameters and perforation distances to meet diverse production needs.

- Cost Efficiency: Achieving significant cost savings while maintaining competitive pricing for optimal value.

- Supplier Independence: Reducing reliance on a single supplier, allowing for more flexibility in sourcing and procurement.

- Comprehensive Support: Offering complete assistance, from sub-assemblies to individual spare parts, ensuring you have everything you need for uninterrupted production.

To receive a quote for your specifically required model or version, just contact out TMQS sales contact or send an email to sales@tmqs.de .

We are looking forward to your enquiry.